Search results for: 'applications magnet free track linear motor technology'

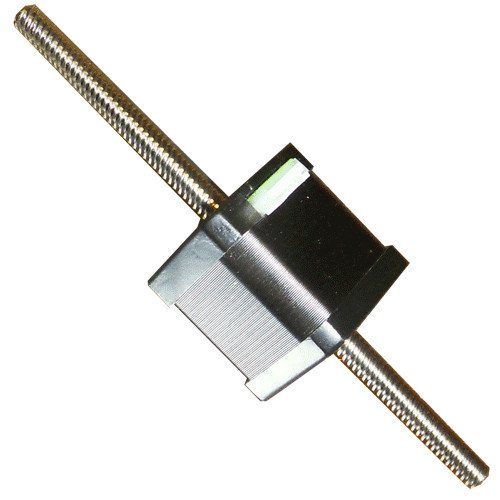

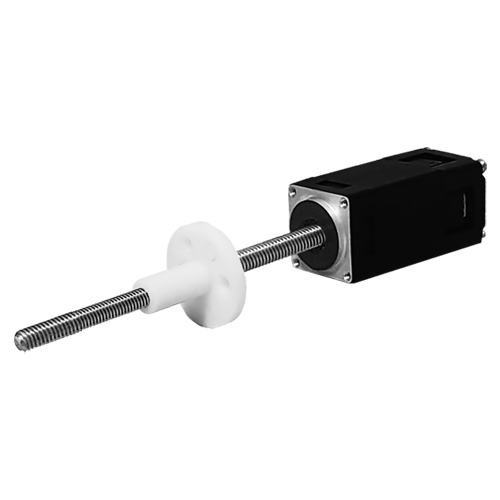

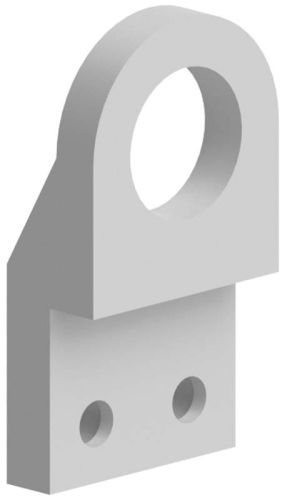

6E21 External Linear Stepper motorAs low as £155.00 £129.170 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

6E21 External Linear Stepper motorAs low as £155.00 £129.170 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

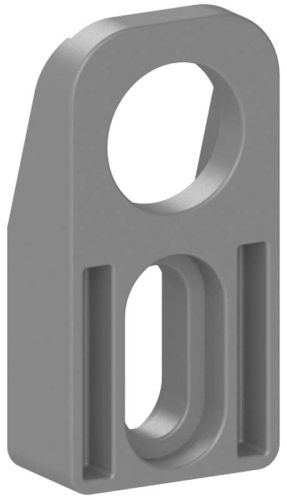

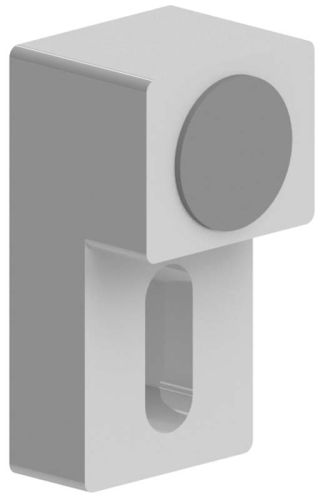

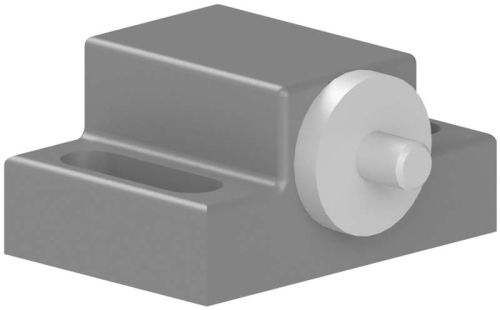

DOOR CLOSER WITH MAGNET - Complete with magnet - (084.524.001)£14.12 £11.770 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

DOOR CLOSER WITH MAGNET - Complete with magnet - (084.524.001)£14.12 £11.770 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

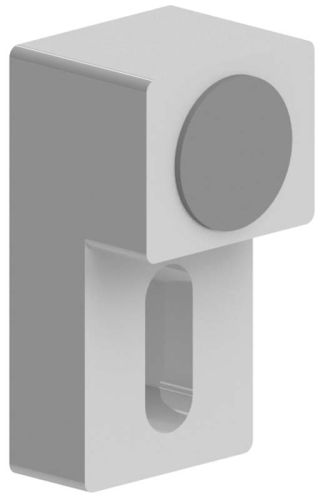

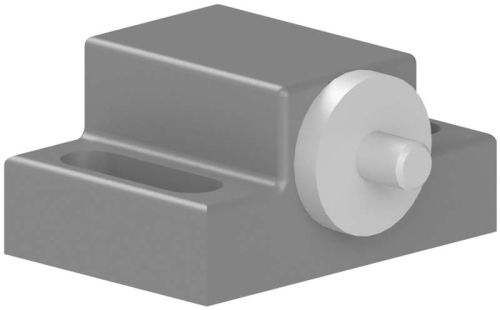

MAGNET DOOR CLOSER - Complete With Strike Plate & Magnet - (084.522.002)£1.97 £1.640 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

MAGNET DOOR CLOSER - Complete With Strike Plate & Magnet - (084.522.002)£1.97 £1.640 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

MAGNET DOOR CLOSER - Complete With Strike Plate & Magnet - (084.525.001)£6.55 £5.464 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

MAGNET DOOR CLOSER - Complete With Strike Plate & Magnet - (084.525.001)£6.55 £5.464 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping SY17STH0404-300A6.35X2X2-P1-EX (External Linear Stepper Motor)£52.74 £43.951 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

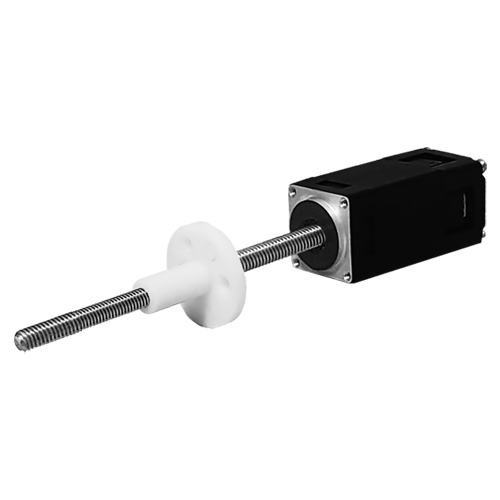

SY17STH0404-300A6.35X2X2-P1-EX (External Linear Stepper Motor)£52.74 £43.951 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping- SY17STH0404-200TR8X8-EX (External Linear Stepper Motor)£45.08 £37.574 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY23STH-2504-100TR11x2-EX (External Linear Stepper Motor)£121.78 £101.487 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY17STH48A6.35-100Ca (Captive Linear Stepper Motor)£61.50 £51.2510 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY17STH1684-300A6.35X2X2-P1-EX (External Linear Stepper Motor)£63.44 £52.870 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY17STH1684-300TR8X4-P1-EX (External Linear Stepper Motor)£60.92 £50.772 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY17STH1684-300TR8X8-EX-ABN (External Linear Stepper Motor)£60.92 £50.779 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY17STH0404-100TR8X8-NON (Non Captive Linear Stepper motor)£37.82 £31.520 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- SY8STH30-0504-100TR3.5X0.61-NON (Non Captive Linear Stepper Motor)£36.90 £30.752 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

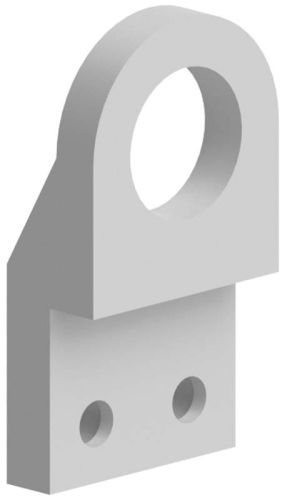

- DOOR CLOSER - For M18 magnet - (084.522.001)£2.09 £1.740 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

- DOOR CLOSER - For M18 magnet - (084.522.003)£1.88 £1.570 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping