Search results for: 'hollow shaft servo linear motor actuators'

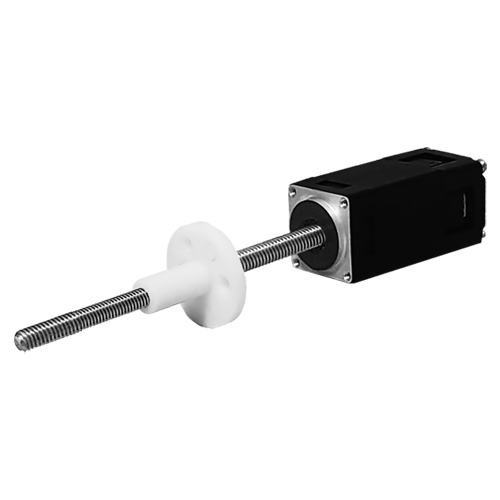

6E21 External Linear Stepper motorAs low as £155.00 £129.170 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

6E21 External Linear Stepper motorAs low as £155.00 £129.170 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

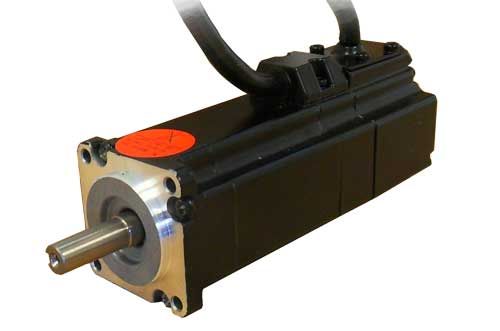

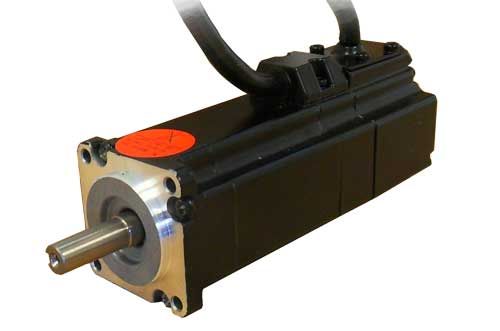

SMH40S-0010-30AAK-4LKH(220V AC Servo Motor )£227.24 £189.370 in stock. - If not in stock expect about 14-21 daysMore Information on Shipping

SMH40S-0010-30AAK-4LKH(220V AC Servo Motor )£227.24 £189.370 in stock. - If not in stock expect about 14-21 daysMore Information on Shipping

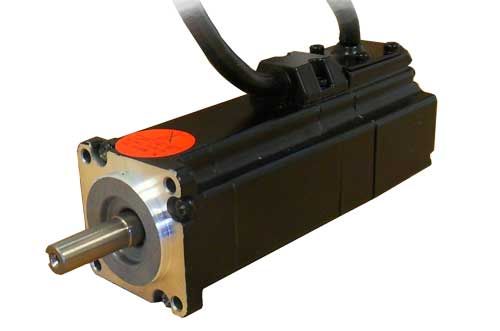

SMH40S-0010-30ABK-4LKH(220V AC Servo Motor )£427.75 £356.460 in stock. - If not in stock expect about 14-21 daysMore Information on Shipping

SMH40S-0010-30ABK-4LKH(220V AC Servo Motor )£427.75 £356.460 in stock. - If not in stock expect about 14-21 daysMore Information on Shipping SMC60S-0020-30MAK-3LKU(220V AC Servo Motor )£193.73 £161.440 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

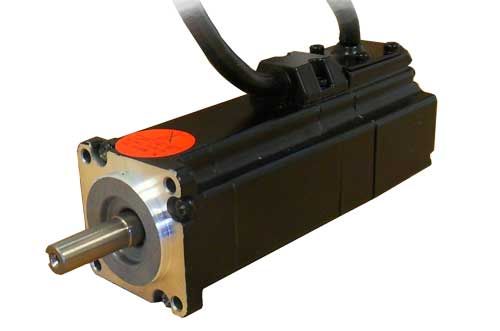

SMC60S-0020-30MAK-3LKU(220V AC Servo Motor )£193.73 £161.440 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping SMC60S-0040-30MAK-3LKU(220V AC Servo Motor )£213.11 £177.590 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

SMC60S-0040-30MAK-3LKU(220V AC Servo Motor )£213.11 £177.590 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping- SMC80S-0075-30MAK-3LKU(220V AC Servo Motor )£361.62 £301.350 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC60S-0020-30MAK-3DSU(Low Voltage DC Servo Motor )£151.08 £125.900 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC60S-0040-30MAK-3DSU(Low Voltage DC Servo Motor )£161.26 £134.380 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC80S-0075-30MAK-3DSU(Low Voltage DC Servo Motor )£190.39 £158.660 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC60S-0020-30AAK-3DSH(Low Voltage DC Servo Motor )£198.89 £165.740 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC60S-0040-30AAK-3DSH(Low Voltage DC Servo Motor )£213.31 £177.760 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC80S-0075-30AAK-3DSH(Low Voltage DC Servo Motor )£255.74 £213.120 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

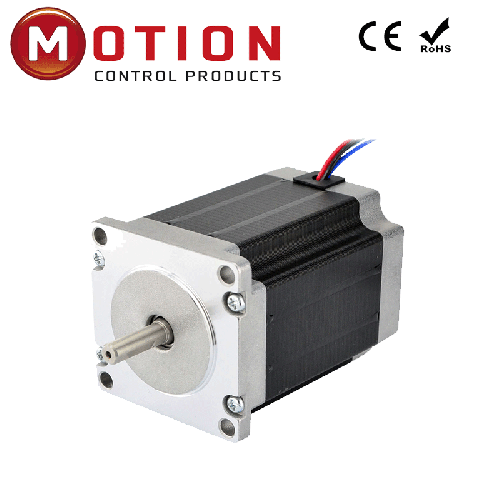

- (M86STH118-4208S-H) NEMA 34 Stepper Motor - Single Shaft£144.78 £120.655 in stock.More Information on Shipping

- (FL20STH33-0604A) 20mm stepper motor with 5mm long shaft£55.46 £46.226 in stock. - If not in stock expect about 14-28 daysMore Information on Shipping

- (M57STH51-3008DC-S) Stepper motor with socket and double shaft£44.03 £36.6916 in stock. (Please contact us to place order)More Information on Shipping

- FD122-AA-000 AC Servo / Stepper Motor Driver£238.68 £198.901 in stock. (If none in stock, please contact us prior to ordering)More Information on Shipping

- (M86STH118-4208DK) NEMA 34 Stepper Motor - double output shaft£144.78 £120.659 in stock.More Information on Shipping

- SMC40S-0005-30MAK-5DSU - (Low Voltage DC Servo Motor )£169.24 £141.030 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC40S-0005-30MBK-5DSU - (Low Voltage DC Servo Motor )£261.54 £217.950 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping

- SMC40S-0010-30MAK-5DSU - (Low Voltage DC Servo Motor )£184.62 £153.850 in stock. (If not in stock expect 4-6 weeks)More Information on Shipping